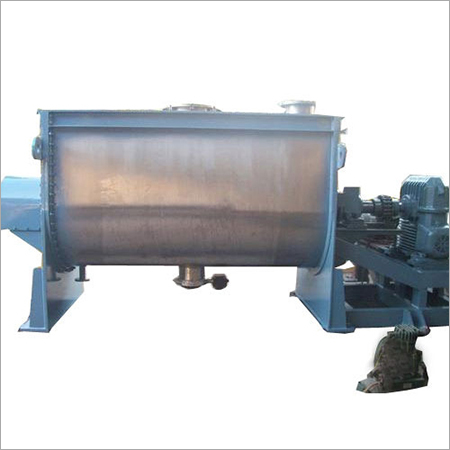

Horizontal Ribbon Blender

Product Details:

- Features Uniform Mixing, Easy Discharge, Low Maintenance

- Mounting Type Floor Mounted

- Drive Type Gearbox Drive

- Mixing Speed 36 RPM

- Voltage 415 V

- Motor Power 7.5 HP

- Application Food, Pharmaceutical, Chemical, Powder Mixing

- Click to view more

X

Horizontal Ribbon Blender Price And Quantity

- 1 Unit

Horizontal Ribbon Blender Product Specifications

- U Shape

- Horizontal Ribbon Blender

- Uniform Mixing, Easy Discharge, Low Maintenance

- Ribbon Blender

- Semi-Automatic

- Gearbox Drive

- Stainless Steel

- Floor Mounted

- 415 V

- 36 RPM

- 60% of Tank Volume

- 5.5 kW

- 750 kg

- 7.5 HP

- Food, Pharmaceutical, Chemical, Powder Mixing

- No

- Horizontal

- 50 Hz

- 500 Liters

- No

- Silver

- Double Helical Ribbon

- 650 mm

- Mirror/Mat Finish

- Standard/Custom Options

- 2500 x 900 x 1200 mm

- Below 80 dB

Horizontal Ribbon Blender Trade Information

- 15 Unit Per Month

- 3 Week

Product Description

Ranking among the topmost firms, we are able to manufacture, export and supply the best gradeHorizontal Ribbon Blender. Under our experts control, this is manufactured using quality-examined components and advanced technology. Examined on certain quality parameters, this is widely demanded in pharmaceutical, food processing, fertilizer and other industries for blending materials. Available in several specifications, thisHorizontal Ribbon Blendercan be bought from us at reasonable rates.

Key Points:

- Easy to operate

- High performance

- Trouble free functioning

- Noiseless operation

Efficient and Versatile Mixing Solution

This horizontal ribbon blender offers uniform mixing for a broad range of materials, including powders, granules, spices, pharmaceuticals, chemicals, and dyes. Its double helical ribbon design ensures quick, even distribution of components, making it suitable for demanding industrial environments.

Durable Construction with Easy Operation

Built with high-quality stainless steel and a robust gearbox drive, the blender delivers reliable performance. The hinged lid with safety grille provides safe yet convenient access, while the standard ON/OFF control panel with interlocks ensures secure operation every time.

Simplified Cleaning and Maintenance

The unit allows for manual cleaning, and optional CIP systems are available for enhanced hygiene. The U-shaped tank and mirror/mat surface finish make it simple to maintain, supporting industries with strict cleanliness requirements.

FAQs of Horizontal Ribbon Blender:

Q: How does the horizontal ribbon blender achieve uniform mixing?

A: The blender uses double helical ribbon blades that rotate at 36 RPM within a U-shaped tank, ensuring thorough and even blending of powders, granules, and other materials during each 1020 minute batch.Q: What types of materials can be processed in this ribbon blender?

A: It is suitable for mixing powders, granules, spices, pharmaceuticals, chemicals, and dyes, catering to a wide range of applications in food, chemical, and pharmaceutical industries.Q: What are the cleaning options for the blender, and how is it performed?

A: The blender can be cleaned manually by opening the hinged lid and accessing the tank. An optional CIP (Clean-in-Place) system is available for industries requiring more automated or stringent hygiene protocols.Q: When should the mixer be operated within its loading capacity?

A: To maintain effective mixing and prevent overloading, its recommended to operate at 60% of the tank volume per batchabout 300 liters in a 500-liter tank.Q: Where can this blender be installed, and what is the required area?

A: It is intended for indoor, floor-mounted installation and requires an area of approximately 3 meters by 1.5 meters, supporting integration into most industrial production facilities.Q: What are the advantages of hinged lid with a safety grille?

A: The hinged lid offers convenient access for loading ingredients and cleaning, while the safety grille helps prevent accidental contact with moving parts, ensuring operator safety.Q: How does the discharge system function, and what types are available?

A: Discharge is achieved either manually or through a valve-operated outlet, enabling controlled and efficient emptying of the mixed batch, which helps in minimizing product loss and ensuring ease of use.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese